|

Model |

Motor power |

Feed Height |

Feed capacity |

Static air Press |

Hopper Capacity |

tube Diameter. |

Demension (cm) |

|

|

Kw /HP |

M |

Kg / H |

pa |

L |

mm |

loader |

hopper |

|

|

SAL-U1HP |

0.75/1 |

4 |

300 |

1600 |

6 |

1.5 |

100*40*50 |

94*53*38 |

|

SAL-U2HP |

1.5/2 |

4 |

400 |

2000 |

12 |

1.5 |

100*40*50 |

132*73*47 |

|

SAL-U3.5HP |

2.4/3.5 |

6 |

800 |

2500 |

24 |

2 |

138*490*590 |

150*78*50 |

|

SAL-U5HP |

3.75/5 |

6 |

1000 |

3000 |

24 |

2 |

138*490*590 |

150*78*50 |

|

SAL-U7.5HP |

5.5/7.5 |

6 |

1200 |

3000 |

36 |

2.5 |

173*58.5*67 |

104*89*63 |

|

SAL-U10HP |

7.5/10 |

8 |

1500 |

4000 |

36 |

2.5 |

173*58.5*67 |

104*59*43 |

|

SAL-U15HP |

10/ 15 |

10 |

2000 |

5000 |

48 |

3 |

173*58.5*67 |

104*59*43 |

|

Notes |

Type of Induction and Carbon on motor is optional. |

|||||||

|

The technical parameter is only for reference, there is no additional notice giving for any alterations |

||||||||

EU auto loader

- Product Detail

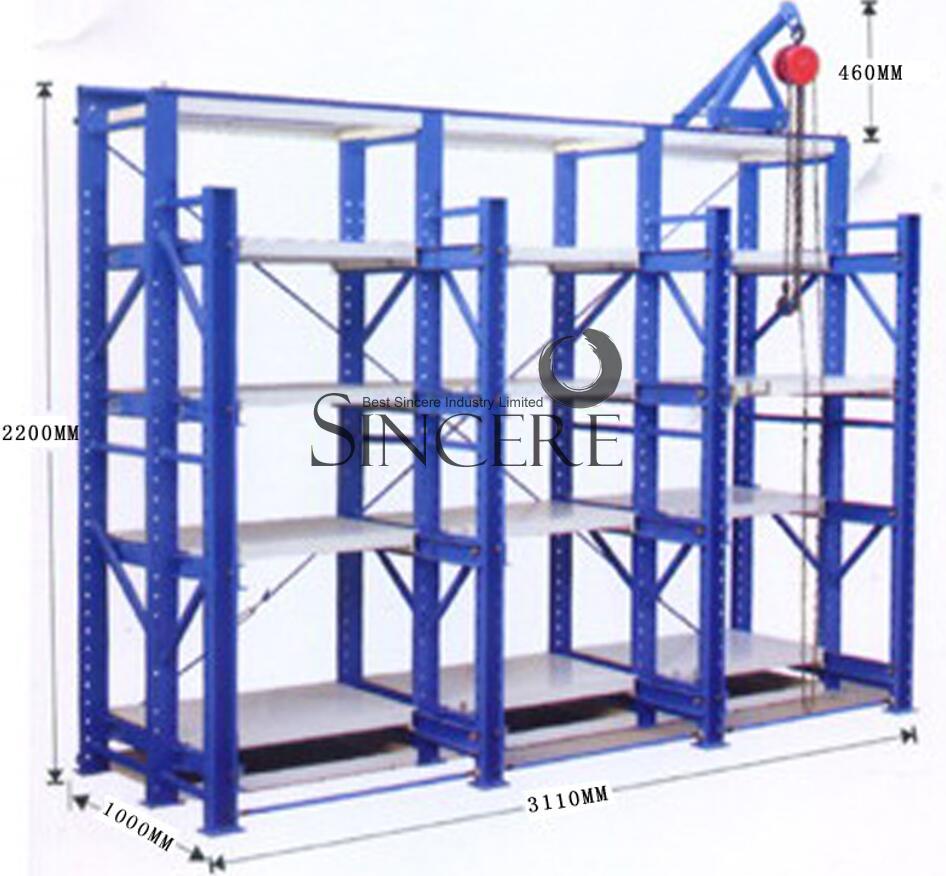

PREVIOUS:Mold frame/Mold rack

NEXT:Big horizontal mixer

English

English Chinese

Chinese BEST SINCERE INDUSTRY LIMITED

BEST SINCERE INDUSTRY LIMITED